Meet Oly, my 1970 Skidoo Olympic 12/3, you may remember her from “Oly get’s a new coat of paint”.

Well, even though the old sled had a full going through times have been rough on old Oly. The first motor decided that enough was enough and started rod hammering like crazy after the first winter. So much so that it was parked for a year in the corner of shame. Then once I was able to track down a new motor, new problems popped up. The new engine was an electric start 320cc Rotax. This meant that it had a larger wattage charging coil/stator under the flywheel, which once started spinning decided to burn out all the bulbs. The taillight I didn’t mind so much but those headlight bulbs are kind of a pain to track down.

Anyways, I had always thought about throwing a nice big fat Kohler 8hp motor in it to get rid of that paint shaker of a Rotax. After fighting back and forth I have now finally bit the bullet and will be putting a 4 stroke in the sled. Its not going to be the Kohler, but a tiny cheap Honda GX200 clone I picked up from Harbor Freight.

So first things first, time to gut the motor out.

Hmm, noticed something broke here that you will see shortly, also 3 of the nuts that old the 8 motor mount bolts in have decided they had better things to do and apparently rattled away.

So the stupid motor mount bar broke in half again. This would be the second one I have replaced on the sled, the Rotax’s vibrate so hard that they just keep snapping them. At this point I realized that only the right side motor mounts actually were holding the motor on. Also the mufflers tip broke off before the tunnel exit, which would explain why it was getting so loud and smokey/sooty under the hood.

Coil wire was in a fight with the belt.

So out with the old and in with the new,

Here is the tiny little Lifan 6.5 motor. With just a intake spacer, new filter, and longer exhaust header these things supposedly put out around 8-9HP with about 13ft/lb of torque. That’s about on par for the Kohler 8hp that they put in early sleds at about half the weight. I’m not looking to have a quick sled here, but something that is rock solid reliable, doesn’t shake or foul plugs, and can just put put around the field and woods all day with no worries on straight gas. So this should fit the bill.

So, things parts that are in the mail:

Comet 94 Duster weighted for 4 strokes at a 1800 RPM engagement speed. 1″ straight bore shaft.

1″ to 3/4″ Shaft adapter with step key.

Governor parts, clone motors have a nasty habit of exploding flywheels at high RPMs

An 88watt lighting coil set and matching flywheel to run the electrics.

So after the above shows up its time to get to it and put this thing together. It should be pretty fun, and I’m exited to have Oly back into a state where it will be reliable enough to just hop on and go anywhere. Slow and steady wins the race, or doesn’t shake and rattle its self to death like a big single Rotax.

——————————————————

Alright, most parts have arrived now with the exception of a few of the governor parts. I also took Oly on a trip into town and de-greased it the best I could while it was in the back of my truck. This however also ended up greasing the trucks cab and windows from all the overspray. But on the plus side it sure beads water well now.

Here is the fancy new 94c Duster along with the shaft adapter and stepped key. Pretty fancy stuff. I did get time to test fit the parts between cutting firewood today and found that the back of the clutch sets to deep on the shaft so it rubs against the block. Now the hunt is on for a shaft bushing/back stop that fits as well as a fairly deep 10mm fine thread bolt to hold this whole mess on the shaft.

—————————————————–

Was a busier then normal day, but I did manage to squeeze in a bit of time to work on getting the clutch mounted.

So this is what the shaft end up looking like. I did have to cut a few inches off the 3/4″ to 1″ adapter as well as shorten the key since the keyway on the clutch is not as long as the key was originally and was preventing it from sliding back on the shaft correctly. Also note the 3/4″ shaft stopper/bushing on the back to keep the clutch from running up against the motor. I picked that up at TSC for around three dollars or so.

You can get a better idea of the back spacing and the stopper working together here, seemed to work out about just right.

And here is the assembled motor/clutch. I couldn’t use the bolt that came with the Comet since it was larger and intended for a one inch shaft. The Lifan GX200 clone has a 10mm threaded shaft with a required bolt length with the clutch on at around 5-6 inches. Since I couldn’t find a bolt that length, I ended up getting a very long standard thread bolt (5/16?) and cut the 10mm x 1.5 pitch threads into it using a die. Then I cut it off at the correct length and ran the die back over the end on the way out. This ended up working out pretty well and we are now ready to move on to making some type of motor mount next.

—————————————————-

Another day another bunch of stuff stuck together.

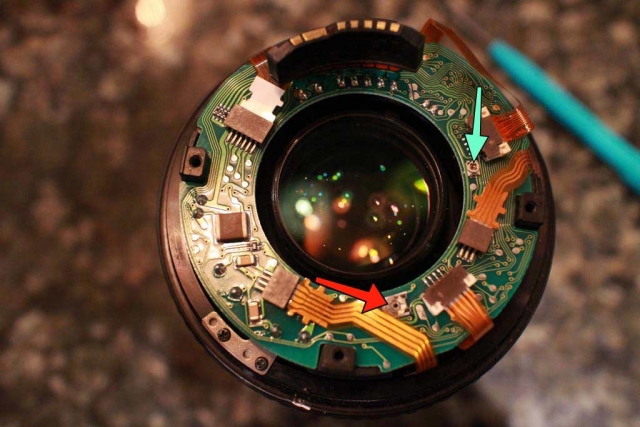

Popped the Lifan’s flywheel off and found that it was ready for the charge coils, yay!

Here is the Baja mini bike flywheel and coil set of dubious quality. The Lifan flywheel looks and feels much safer and better built then this thing, but oh well.

My amazing hacked together motor mount. Needs a few tweaks yet to keep the studs from popping out the top but its close to being finished.

Motor in place on a test fit. This may actually work!

—————————————————

Spent some time today cleaning up and finishing the motor mount, its not the prettiest thing but it should do the job. As an added bonus its also rattle canned “Not rusty anymore black”.

Started fiddling around with the governor linkage trying to get that mess sorted out, but its going to take a bit more tinkering I think. Also its about time for another order of parts to be placed, going to need some muffler/header bits, fuel pump, pulse adapter, and an airfilter assembly. That should help get it fully integrated into the sled instead of leaving it looking like a rototiller motor stuck on top of a snowmobile.

————————————————–

I think that its almost ready to be fired up now. The order I placed for exhaust parts and the air filter showed up, plus I got the governor back on and the oil changed. Still need to find some time to get the exhaust plumed up. Slightly concerned about how loose the belt is, but worse come to worse I may slot the motor mounts and pull it back about a half inch. Going to put the Rotax back in it for a test fit/measure before doing that though.

Small things to note at this point:

The stock gas tank does not fit under the handle bars with the square stock motor mount I made, it may be tight even with just a flat bar mount.

The aftermarket airfilter looks like it may clunk into your knee and get annoying due to how far it hangs out the side. If this becomes an issue I may cut the filter off near its base so that I have a short rubber tube. Then get some wire screen and overlay it, and sandwhich some foam between it. This will make a nice stumpy air filter. Snowmobiles don’t need big dust blocking filters anyways, just something to keep dead grass out mostly.

————————————————–

You want another crappy cell phone pic!? Good news! Here’s a new one! So any ways, throttles hooked up, headers made, and I re-purposed an old muffler I had kicking around forever. Still need to get the muffler attached solidly, but that’s what hose clamps are for. Fuel pump should be in tomorrow and hopefully I can finally start this thing up.

—————————————————

Another edit, another update. Was able to get Oly out in the snow after finishing up the fuel pump and playing with the throttle linkages, and all in all it was pretty fun! Its not all that fast, but its very smooth and quiet. The little motor seems to have more then enough gumpf to pull its self around the yard. There was lots of lowend torque and it puttered about around 10mph or so. I did find out that I had horribly screwed up the belt alignment and tension with the motors position. I was thinking about salvaging the mount but then decided it would st be easier to build something newer, lighter, and more adjustable.

So here’s the new mount which is all aluminum. I used an old Skidoo service manual this time to set the proper sheave alignment on the clutches, and made sure this time to build some adjustment into the motor mount. In the above picture you can see that I bored the back a little larger then the fronts, this way I could have some side to side adjustment on the clutch faces for alignment. Also, which the picture does not show, I ended up slotting the motor mount holes where it bolts to the frame, giving about an inch and a half of front to back adjustment for belt deflection adjustment. So now the belt is properly aligned and tight.

There’s no snow on the ground due to a thaw that rolled through, but the clutch seems to be working much better when tested on the stand. Its grabbing early, seems to be shifting better, and is not skewed a few inches to the side.

Now once some snow comes back, I can get back to adjusting the carb and governor which then just leaves the electrical left to tackle. Have been toying around with the idea of using LED’s this time but will more then likely end up using the stock bulbs for now.

—————————————————

Well, it took almost a month and a half but we finally got some decent snow on the ground for another test run. Before that though, let me backup a bit and cover the electrical system update.

So, I was going back and forth on LED or no LED bulbs, and ended up sticking with the sleds normal lights. I did however pick up a small 35watt halogen that I may or may not put on at a later date. It was a couple bucks so I figured what the heck. For a battery I snagged off amazon a small 12v sealed backup battery for a Chamberlain garage door. I think it was around 19.99 or so. Also in the mix was a used rectifier I dug up on ebay for 5 bucks that was off a 2004 Honda CRF 230F.

And here is everything installed. I tried to keep it as neat as I could, although if you started with a clone engine that had electric start on it already you would be better off I imagine. Anyways the battery is not resting on the tunnel, but is clamped to the motor mount by a bar and two bolts. On the front if this is the rectifier, which then runs up to the light switch on the dash. Beyond that its just the stock wiring to the head light tail lights. I still need to get some tail light bulbs.

So here is the final product:

So how does a full size snowmobile run with a 6.5HP motor in it? The best way I think to describe it would be like riding a rototiller through the snow. Its fun, very fun, and very slow, if any of that makes sense.

Flats: On hard pack it will do about 15-20mph depending. In snow over 3-4 inches it slows down to around 10mph or so. Deep snow, like a 5 foot drift I was playing in makes it drop to about 5-7mph. It does not get stuck, since there’s not enough power to spin the track. Its also light enough that it floats on top without sinking, chugging through the snow like a pokey donkey.

Hills: On hard pack downhill it will hit about 20-25mph, up hill slows to about 7mph or so. Off in deeper snow it stays at around 5-7mph. The motor never really changes tone or sounds like its being worked hard, the clutch seems to just take up the slack as it shifts way down. (Note that I left the governor on it on purpose, if you reach down and yank it wide open there is a lot more to gain.)

Its kind of hard to add all this up and convey how it rides with any sort of justice. Its just fun, and it makes you smile, its pretty much all the best parts of riding a vintage snowmobile with none of the worries of riding a vintage snowmobile. The motor sips gas, its quiet, there is no mix to worry about, it can idle all day without fouling a plug, you cant go fast enough to get into trouble or hit something, and those thoughts in the back of your head about how far out from the house can you go before something breaks seems to be pretty much gone. I think I may have to convert my old Foxtrac with the 13hp Honda clone next, this is a hoot.